Pressure transmitter/SM39PWB-DFLYC single flange remote diaphragm pressure transmitter

Product Categories Pressure transmitter

The diaphragm box of the remote transmitter is used to prevent the medium in the pipeline from directly entering the pressure sensor component of the transmitter. The pressure is transmitted between it and the transmitter using a filling liquid such as silicone oil. The SM39PWB-DFLYC series gauge pressure/absolute pressure remote transmitter is used to measure the liquid level, density, and pressure of liquid, gas or steam, and then convert it into a 4mA~20mADC HART current signal output. It can also communicate with the HART handheld terminal to set parameters and monitor the process. The measurement range of the SM39PWB-DFLYC series gauge pressure/absolute pressure remote transmitter (when not migrated) is 0-6kPa~25MPa, and the rated pressure of the remote flange is: 1.6/4MPa, 6.4MPa 10MPa, 150psi, 300psi or 600psi.

- application

The diaphragm box of the remote transmitter is used to prevent the medium in the pipeline from directly entering the pressure sensor component of the transmitter. Silicone oil and other filling liquids are used to transmit pressure between it and the transmitter.

SM39PWB-DFLYC series gauge pressure/absolute pressure remote transmitter is used to measure the level, density and pressure of liquid, gas or steam, and then convert it into 4mA~20mADC HART current signal output.

It can also communicate with HART handheld terminals to perform parameter setting, process monitoring, etc.

The measuring range of SM39PWB-DFLYC series gauge pressure/absolute pressure remote transmitter (when not migrated) is 0-6kPa~25MPa, and the rated pressure of the remote transmission flange is: 1.6/4MPa, 6.4MPa 10MPa, 150psi, 300psi or 600psi.

- Working principle and structure

The SM39PWB-DFLYC series gauge pressure/absolute pressure remote transmitter is composed of the SM39PWB-DFLYC series gauge pressure/absolute pressure transmitter and the remote transmission flange with capillary installed by welding. Its working principle is the same as that of the SM39PWB-DFLYC series gauge pressure/absolute pressure transmitter, but the pressure transmission path is slightly different: the pressure acting on the remote transmission flange side first passes through the diaphragm and filling liquid on the remote transmission flange, then through the capillary, and finally reaches the measuring end of the measuring sensor.

- enter

Measuring parameters: gauge pressure, absolute pressure, liquid level measurement range

Gauge pressure remote transmitter:

Lower limit: -100%URL (continuously adjustable)

Upper limit: to +100%URL (continuously adjustable)

Absolute pressure remote transmitter:

Lower limit: 0%~100%URL (continuously adjustable)

Upper limit: to +100%URL (continuously adjustable)

- Output

Output signal

Two-wire system, 4mA~20mADC HART output, digital communication, HART protocol is loaded on 4mA~20mADC signal. Output signal limit: Imin=3.9mA, Imax=20.5mA

- Response time

The damping constant of the amplifier component is 0.1s; the time constant of the sensor and remote flange is 0.2s to 6s, depending on the sensor range, range ratio, capillary length, and the viscosity of the filling liquid. The additional adjustable time constant is: 0.1s to 60s.

- General conditions

-

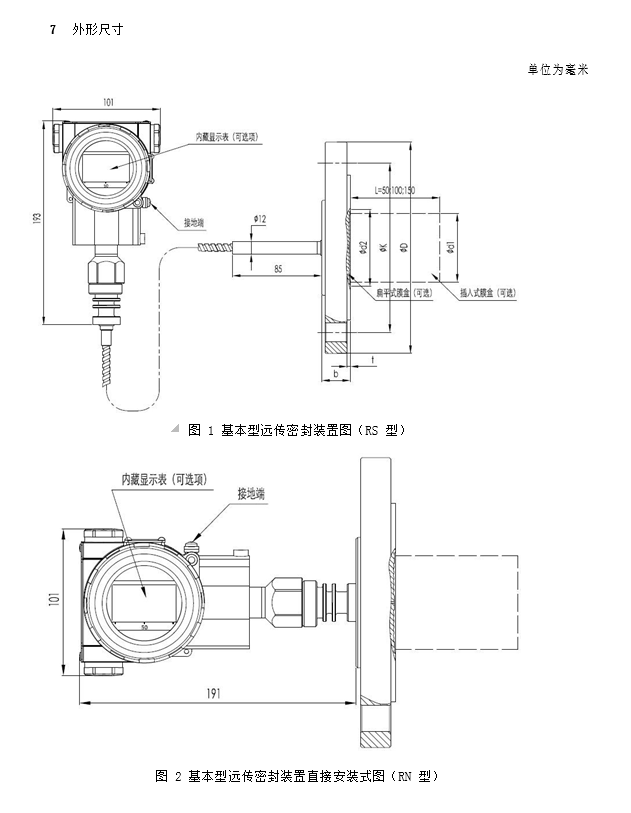

- Installation conditions

Gauge/absolute pressure transmitters without capillaries can be mounted directly via the remote flange, and position deviations will result in a correctable zero offset. The electronic housing can be rotated up to 360° and set screws can be used to fix it in any position.

The gauge pressure/absolute pressure remote transmission flange is connected to the matching flange that complies with ANSI/DIN standards. The matching flange should be equipped with soft gaskets and mounting bolts and nuts (users can choose mounting bolts and nuts).

For gauge pressure/absolute pressure remote transmitters with capillaries, if the remote sealing device is lower than the transmitter body, the maximum height difference between the remote sealing device and the transmitter body should be <5m.

When the working pressure is lower than 100kPa absolute pressure, the transmitter body must be lower than the remote sealing device. The minimum bending radius of the capillary is 75mm, and winding is strictly prohibited!

-

- Environmental conditions

Ambient temperature

Minimum: Depends on filling fluid Maximum: 85°C

With LCD display, fluororubber sealing ring -20℃~65℃ Storage temperature/transportation temperature

Minimum: Depends on filling fluid Maximum: 85°C

Relative humidity: 0%~100% Shock resistance

Acceleration: 50g

Duration: 11ms Anti-vibration

2g to 500Hz Electromagnetic Compatibility (EMC)

See Table 4 "Electromagnetic Compatibility Appendix" on the next page

-

- Process medium limit temperature Limit medium temperature: -30℃~400℃

Table 3 Relationship between filling fluid, operating temperature and minimum operating pressure

| Filling fluid | Silicone oil (S) | High temperature silicone oil (H) | Ultra-high temperature silicone oil (U) | Vegetable oil (V) |

| Density (25℃) | 960kg/m³ | 980kg/m³ | 1020kg/m³ | 937kg/m³ |

| Operating temperature range | -30℃~200℃ | -10℃~350℃ | -10℃~400℃ | 0℃~250℃ |

| temperature | Working static pressure range (kPa absolute pressure) | |||

| 20℃ | >10 | >10 | >10 | >25 |

| 100℃ | >25 | >25 | >25 | >50 |

| 150℃ | >50 | >50 | >50 | >75 |

| 200℃ | >75 | >75 | >75 | >100 |

| 250℃ | >100 | >100 | >100 | |

| 350℃ | >100 | >100 | ||

| 400℃ | >100 | |||

Note: If the working temperature and pressure relationship exceeds the above range, it should be specially pointed out and can be met through special design.

Transmitter body pressure limit: vacuum to maximum pressure

Remote transmission flange rated pressure:

ANSI standard: 150psi~600psi DIN standard: PN 1.6MPa~PN 10MPa

weight:

DN 50/2″ is about 7kg~10kg, DN 80/3″ is about 8kg~11kg, DN 4″ is about 9kg~12kg.

Explosion-proof performance:

NEPSI explosion-proof license: Ex dⅡC T6 NEPSI intrinsic safety license: Ex iaⅡC T4 Allowable operating temperature: -40℃~65℃

6.4 Power supply and load conditions

The power supply voltage is 24V

R≤(Us-12V)/Imax kΩ Where Imax=23 mA

Maximum power supply voltage: 42VDC, minimum power supply voltage: 12VDC, 15VDC (backlit LCD display)

Digital communication load range: 250Ω~600Ω

Material:

Measuring membrane box: stainless steel 316L

Diaphragm: Stainless steel 316L, Hastelloy C, Tantalum Process flange: Stainless steel 304

Filling fluid: Silicone oil, high temperature silicone oil, ultra-high temperature silicone oil, vegetable oil Transmitter housing: Aluminum alloy, surface sprayed with epoxy resin

Housing seal: Nitrile rubber (NBR)

Nameplate: Stainless steel 304 Electrical connections:

M20×1.5 cable gland, wiring terminals are suitable for wires with a diameter of 0.5mm2 to 2.5mm2. Process connection:

The remote transmission flange complies with ANSI or DIN standards. It can be directly installed, refer to the dimension table.

Enclosure protection grade:

IP67

Table 4 Electromagnetic compatibility appendix

| Serial number | Test items | Basic Standards | Test conditions | Performance level |

| 1 | Radiated interference (housing) | GB/T 9254-2008 Table 5 | 30MHz~1000MHz | qualified |

| 2 | Conducted interference (DC power port) | GB/T 9254-2008 Table 1 | 0.15MHz~30MHz | qualified |

| 3 | Electrostatic Discharge (ESD) Immunity | GB/T 17626.2-2006 | 4kV (contact) 8kV (air) | B |

| 4 | Radio frequency electromagnetic field immunity | GB/T 17626.3-2006 | 10V/m (80MHz~1GHz) | A |

| 5 | Power frequency magnetic field immunity | GB/T 17626.8-2006 | 30A/m | A |

| 6 | Electrical fast transient burst immunity | GB/T 17626.4-2008 | 2kV(5/50ns,5kHz) | B |

| 7 | Surge immunity | GB/T 17626.5-2008 | 1kV (between lines) 2kV (between lines and ground) (1.2us/50us) | B |

| 8 | Immunity to conducted disturbances induced by radio frequency fields | GB/T 17626.6-2008 | 3V(150kHz~80MHz) | A |

Selection of pressure/absolute pressure remote transmission seals with internal diaphragms

| Remote seal with internal diaphragm | |||||||||||

| UN - Direct mount, no capillaries | |||||||||||

| US- | With capillary | ||||||||||

| Process connection | Nominal diameter | Sealing surface form | Rated pressure | ||||||||

| A | DN25 DIN 2501 | D type DN2526 | PN 1MPa/4MPa | ||||||||

| B | DN25 DIN 2501 | D type DN2526 | PN 6.3MPa/10MPa | ||||||||

| C | DN25 DIN 2501 | D type DN2526 | PN 16MPa | ||||||||

| D | DN25 DIN2501 | E type DN2526 | PN 25MPa | ||||||||

| E | DN1″ANSI B 16.5 | RF type ANSI B 16.5 | 150psi | ||||||||

| F | DN1″ANSI B 16.5 | RF type ANSI B 16.5 | 300psi | ||||||||

| G | DN1″ANSI B 16.5 | RF type ANSI B 16.5 | 600psi | ||||||||

| H | DN1″ANSI B 16.5 | RF type ANSI B 16.5 | 1500psi | ||||||||

| Code Filling fluid | |||||||||||

| S Silicone oil -30℃~200℃ | |||||||||||

| H High temperature silicone oil -10℃~350℃ | |||||||||||

| V Vegetable oil 0℃~250℃ | |||||||||||

| Code | Capillary length | ||||||||||

| 1 | 1m | ||||||||||

| 2 | 2m | ||||||||||

| 3 | 3m | ||||||||||

| 4 | 4m | ||||||||||

| 5 | 5m | ||||||||||

| 6 | 6m | ||||||||||

| S | Special length | ||||||||||

| Code Capillary Component Features | |||||||||||

| N None | |||||||||||

| P Capillary tube with PVC cover | |||||||||||

Selection of threaded gauge pressure/absolute pressure remote transmission seal device

| Threaded mounting gauge pressure/absolute pressure remote transmission sealing device | |||||||||||

| TS- with capillary | |||||||||||

| Code | Diaphragm/seal material | ||||||||||

| U | Stainless steel 316L | ||||||||||

| V | Hastelloy C | ||||||||||

| W | Tantalum | ||||||||||

| Code | Flush spare hole | ||||||||||

| 1 | none | ||||||||||

| 0 | have | ||||||||||

| Code | Filling fluid | ||||||||||

| S | Silicone oil -30℃~200℃ | ||||||||||

| H | High temperature silicone oil -10℃~350℃ | ||||||||||

| U | Ultra-high temperature silicone oil -10℃~400℃ | ||||||||||

| V | Vegetable oil 0℃~250℃ | ||||||||||

| Code | Capillary length | ||||||||||

| 1 | 1m | ||||||||||

| 2 | 2m | ||||||||||

| 3 | 3m | ||||||||||

| 4 | 4m | ||||||||||

| 5 | 5m | ||||||||||

| 6 | 6m | ||||||||||

| 8 | 8m | ||||||||||

| S | Special length | ||||||||||

| Code Capillary Component Features | |||||||||||

| N None | |||||||||||

| P Capillary tube with PVC cover | |||||||||||